MDF VS Particle Board – 15 Important Differences

Solid wood is a preferred finishing material for all types of furniture, but it comes with one glaring disadvantage, which is cost.

Furniture Manufacturers often reduce the overall cost of their products by using MDF and particleboard. Both MDF and particleboard are composite materials. The big advantage is that this wood alternative is much less expensive and can be created with a level of consistency.

So, In this article, we are going to discuss the differences between MDF and particle boards.

So let’s begin,

MDF vs Particle Board

1). How it is made

The long form of MDF is medium-density fiberboards. These are made from wood fibers. These wood fibers are mixed with glue and it goes through a hot Press machine which compresses the mixture and forms aboard.

Whereas,

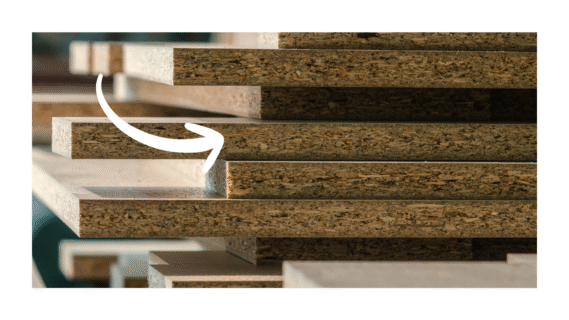

Particle Board is an engineered wood product made from Waste products like wood chips, sawdust, and wood shavings. These are mixed with glue such as urea-formaldehyde resin or phenolic resin and this mixture is firmly compressed by pressing under heat and pressure to form a particle board.

2). Appearance

MDF has more surface as it is made from wood grains of uniform size.

Whereas,

Particle Board contains wood chips and wood shavings and it doesn’t have a smooth surface.

3). Density

MDF is denser than particle board.

Whereas,

Particle Board has less density as compared to MDF.

4). Strength

MDF is stronger than particle board.

Whereas,

Particle Board has less strength as compared to MDF.

5). Durability

MDF is fairly durable compared to particle boards.

Whereas,

Particle boards are less durable as compared to MDF.

6). Voids

MDF doesn’t contain any voids.

Whereas,

Particle Board contains voids.

7). Weight

MDF boards are heavier in weight than particle boards.

Whereas,

Particle boards are lightweight as compared to MDF.

8). IS Code To Be Followed

The Indian Standard Quality Specification for MDF is prescribed in documents IS:12406 and IS:14857.

Whereas,

For particle boards, the Indian Standard quality specification is given in documents IS:3087 and IS:12823.

9). Moisture Resistance

MDF has more resistance to water as it has fewer voids.

Whereas,

Particle board has less resistance to water as its soaks water.

10). Resistance to Warping & Cracking

MDF has more resistance to warping and cracking as compared to particle boards.

Whereas,

Particle board has low resistance to warping and cracking as compared to MDF.

11). Load Carrying Capacity

MDF has a good load-carrying capacity as compared to particle board.

Whereas,

Particle boards cannot support heavy loads.

12). Screw Holding Capacity

MDF has a low screw-holding capacity as compared to particle board.

Whereas,

Particle boards have more screw-holding capacity as compared to MDF.

13). Uses

MDF is preferred by manufacturers for high-end furniture like cabinets, shelves, etc. It is also used for interior decor in restaurants and homes.

Whereas,

Particle board is commonly used in lower-end lightweight furniture. like shoe racks, portable furniture, children’s furniture, computer tables, wardrobes, etc.

14). Painting

MDF can be painted easily.

Whereas,

Particle board cannot be easily painted as it soaks paint.

15). Lifespan

In a dry environment MDF can last up to 10 years, and if it is laminated then it can last up to 15 to 20 years.

Whereas,

In the case of particle board, it can last up to 5 years in a dry environment and if it is laminated then it can last up to 10 to 15 years.

16). Price

MDF boards are costlier as compared to particle boards. The price of MDF depends on the thickness, quality, and brand.

Whereas,

Particle boards are cheaper as compared to MDF.

Product Suggested

Thanks For the Great Attention!

Also, Read,

Related Video,

MDF VS Particle Board