Technical Terms of Reinforcement

Reinforcement technical terms – As a fresh civil engineer, you must know these technical terms for reinforcement. These terms are very important for the Bar bending schedule as well as in site execution.

75 Technical terms of reinforcement

2). Weight of Steel per Rmt?

a). Weight of steel in kg = d2/162.2kg/meter

b). Weight of steel in feet = d2/533kg/ft

3). Standard Length of MS Bar?

The standard length of a deformed ( MS ) Mild steel bar is 40′ or 12 meters.

4). Full form of different types of bars

[table “2” not found /]

5 ). Types of Steel Bars.

Mild Steel = Fe 250 N/mm 2

H Y S D = Fe 415 or Fe 500 N/ mm2.

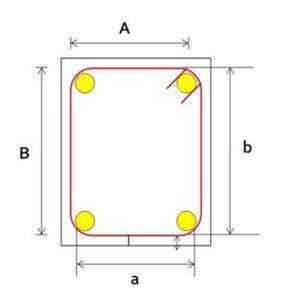

6). Minimum Longitudinal Bar in a Column?

A square-shaped column should have 4 bars.

A round Shape column should have a minimum of 6 numbers of bars.

7). Required bending wire

For binding, one ton of steel reinforcement binding wire required 7 kg to 13 kg.

8). Chair

The diameter of the MS bar for the chair shouldn’t be less than 12 mm.

9). Chair

The Maximum Chair spacing should be 1.00 m (or) 1 No per 1 meter square

10). Unite the Weight of the Steel bar

[table “3” not found /]

11). C/C means center-to-center distance.

12). D L means Development Length

13). T M T means Thermo Mechanically treated bars.

14). The transverse reinforcement provided in columns is called Ties.

15). The transverse reinforcement provided in Beams is called Stirrups.

16). Minimum Diameter of the bar in the Slab is 8 mm.

17). The minimum diameter of the bar in the Column is 12 mm.

18). The maximum diameter of steel in the column is 50 mm.

19). Why cover block is used in Reinforcement

i). To maintain a Unique & specific distance between rebars and shuttering.

ii). To protect steel reinforcement from corrosion.

iii). To provide thermal insulation for contract and expansion.

20). Always use a minimum of 12 mm diameter of steel bars at the bottom of the plinth beam.

21 ). Always use a minimum of 10 mm diameter of steel bars at the Top of the plinth beam.

22). The Minimum Size of the R.C.C Column is 9’’ x 9’’ or 230 mm x 230 mm with a minimum of 4 bars of 12 mm steel of grade Fe 500.

23). The Minimum Concrete grade in the column is M20.

24). Always use 8 mm stirrups at a spacing of 150 mm center to center throughout the Column length.

25). Deflection Means

Temporary displacement.

26). Why do we use only Steel as a Reinforcement

Because of the coefficient of thermal expansion.

27). Density of Steel is 7850 Kg/cum.

28). Why deformation is Provided in Steel Bar

i). To prevent the Slipping of Bars from concrete.

ii). To increase the bond strength between steel and concrete.

29). Lung’s height of steel bars?

It should not be greater than 0.004 to 0.005 times the diameter of the bars.

For example:-

diameter of the bar is 10 mm

Lugs height = 0.04 x 10 = 0.4 mm.

For a 32 mm diameter bar

Lugs height = 0.04 x 32 = 1.28 mm.

30). The angle of steel bars should not be greater than 45 degrees.

31). Fe means the yield strength of bars is 500 N/Square mm.

32). Lap Length

The length of steel used for transferring the loaded steel to steel and used for bonding two steel.

33). Development Length

The length of steel that we require to transfer the load of one member to another is called Development length (Ld).

34). Development length ( L d) depends upon.

i). Grades of steel Fe 415, 500, 500 d, 600

ii). Depends on the grades of concrete.

35). The distance between two lapping in different bars should not be less than 1.3 meters or 1300 mm from the center of lapping or less than 13 times.

36). In the case of higher or lesser diameter bars always consider a less diameter bar for lapping length.

37). Always tilt the bar when lapping two bars.

38). The limit of tilting of the bar is 75 mm or 6 d.

39). The minimum diameter used for dowel bars should be 12 mm.

40). Why do we provide Steel in Concrete?

The tensile strength and strain capacities of concrete are very brittle; hence, We used Reinforcement to balance this deficiency.

41). Binding Wire?

The binding wire is used to tie the steel bars at every intersection with two strands (wire) of annealed steel wire having a diameter of 0.9 to 1.6 mm thickness.

42). Reinforcement Steel Bars.

Steel Reinforcement is commonly known as ‘Rebars’. We provide steel bars in concrete for R.C.C. structure Tensile strength.

43). Important IS Code

IS: 1786 – Reinforcement Steel – HYSD Rebars -(Physical & Chemical Properties)

IS 2502 – BBS – Code for bending and fixing of bar reinforcement.

44). Percentage of steel in structural members

i). Slab – 1 % of the total volume of concrete.

ii). Beam – 2 % of the total volume of concrete.

iii). Column – 2.5 % of the total volume of concrete.

iv). Footings – 0.8 % of the total volume of concrete.

45). Thumb Rule for steel Reinforcement quantity required for slab, Beams, Footings & Columns

Steel required in Residential buildings = 4.5 Kg – 4.75 Kg / sq. ft.

Steel required for Commercial building = 5.0 kg – 5.50 Kg/Sq. ft.

46). As per Area Maximum Reinforcement.

Beam & Slab = 4 % of Gross Area.

Column = 6 % of Gross Area.

47). Strength of Reinforcement should not be less than 15 % of its designated strength.

48). Carbon Percentage in Steel.

0.23 %.

49). Placing 1st Stirrup

The 1st stirrup of the beam must be placed within 2″ of the support.

50). No. of Stirrups

= (Clearspan/ c /c Spacing) + 1.

51). Minimum “L” for column main rod in footing is 300 mm.

52). All Reinforcement used should be free from mill scales, loose rust & coats of paint, oil, or any other substances.

53). For the Cantilever main steel anchorage length is 69 D.

54). As per IS 456: 2000

The maximum diameter of the Steel bar used in the slab should not exceed 1/8th of the total Slab thickness.

55). Main bars in the slabs shall not be less than 8 mm (H Y S D) or 10 mm (Plain bars).

56). Distribution bars Should not be less than 8 mm and not more than 1/8 of slab thickness.

57). Lap length for M 20 concrete?

Columns – 45 d.

Beams – 60 d.

Slabs – 60 d.

58). Lapping Bars Should be Provided at the end of the support.

59). Lapping should be closely spaced at the lapping zone.

60). Lapping should be done in the middle 3rd position of the beam.

61). Never provide lapping in the center of the beam and column.

62). Lapping of bars should be alternated in the beam.

63). Lapping length should not be less than 75 mm. as per IS Code 456 – 2000.

64). Maximum Lap in a Zone.

More than 50% of bars shouldn’t be lapped in one zone.

Don’t use more than 50% lapping zone in any R.C.C. structure.

65). Lap in the Tension zone.

No lapping should be placed in the tension zone.

66). Lap in the compression zone.

Steel should be lapping for the compression zone with 50 d where ( d ) is the diameter of the steel bar.

67). Lapping or Lap slices of bars are not allowed to have diameters more than 36 mm.

68). Bent Up bar.

Always Provide a bent-up bar near at support of the slab and beam.

69). To handle the shear force and to keep longitudinal bars in position Stirrups in Beams and Ties in Columns are provided.

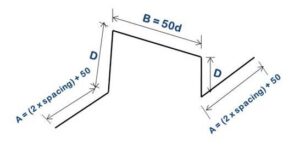

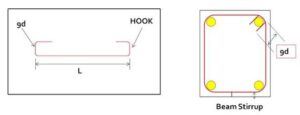

70). Length of the Hook should not be less than 9 D (Diameter of Bar) for one side.

71). Hook’s Angle of Stirrup.

The hook angle of stirrups is 135°.

72). Bend for the Vertical Bar of the Column.

Always remember that vertical column bars are known as longitudinal bars and the longitudinal bars should be bent at 90 degrees & length should not be less than 18’’ or 1.5 feet.

73). The Cantilever Beam has One fixed support and the other end is free.

74). A simply supported beam has a minimum of two supports which is fixed support.

75). Slabs.

i). One Way Slab = L y / L x > 2

Spanning in one direction only.

ii). Two Way Slab = L y / L x < 2

Spanning in both directions.

I earnestly hope that these Technical terms of reinforcement have been both meaningful and useful to you & help you to make your house construction perfect.

If you like this article then please share it with your friends & also like our Facebook Page and join our Telegram Channel.

Thanks For the Great Attention!

Also, Read

1000Sqft House Construction Cost

Technical Terms of Reinforcement